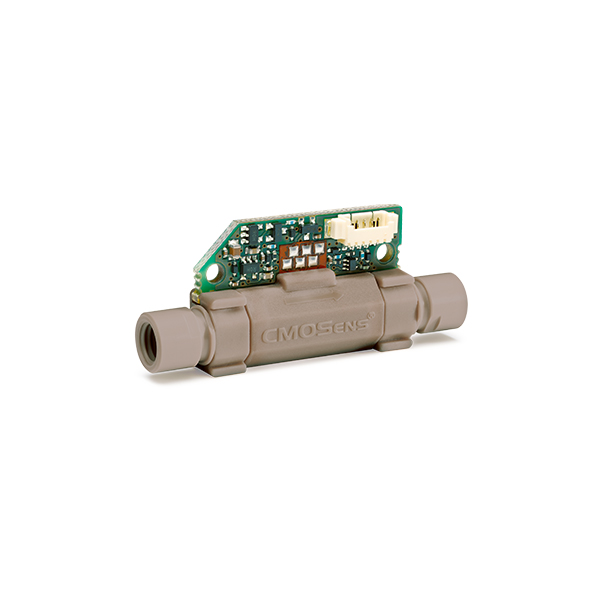

For Integration into Instruments and Other Closed Systems

The LG16 liquid flow meters offer Sensirion’s CMOSens® microsensors in a compact and stripped-down housing for integration into instruments and other closed systems. With five different flow ranges, calibration options for different media (H 2O and/or hydrocarbons), and digital I2C interface, the LG16 liquid flow meters offer a comprehensive solution for measuring low and ultra-low flow rates. All subtypes feature the strengths of Sensirion’s liquid flow meters: fully calibrated digital flow sensing, inert wetted materials (glass, PEEK, fluoropolymer), fast response times (down to 40 ms and below), and low power consumption.

They offer the ideal solution for measuring highly dynamic fluidic processes, closed-loop control of microfluidic systems, bead and droplet count, or bubble detection. The 5 subtypes cover maximum flow rates from 1.5 µl/min by the smallest version (LG16-0025) up to 10 ml/min (LG16-2000) for water and aqueous solutions. With hydrocarbon liquids such as oils, organic solvents, fuel, or lubricants, flow rates up to 80 ml/min can be measured (see LG16-2000HC-D).

The LG16 liquid flow meters have their largest benefit when integrated into an instrument or a closed system. For standalone applications, laboratory setups or bench-top testing, please have a look at our SLx liquid flow meters with their robust interface for plug-and-play operation.

Sensor Evaluation

For quick and easy testing, the corresponding SLG or SLI ready-to-use kit is. Together with the provided software, it enables a plug and play connection of the sensor to a PC. The corresponding SLG/SLI evaluation kit can be ordered from our distributors.

Features:

- Highly integrated: Linearized, temperature-compensated and fully calibrated digital output signal (I2C) from a single chip

- Calibrated for water and IPA up to +/- 40 ml /min

- Turn down ratio 200:1 or better

- High speed measurement: Response time below 20 ms

- Bidirectional measurement and real time failure detection

- Easy fluidic and electrical integration via ¼″-28 flat bottom ports and a standard connector

- Straight, unobstructed flow channel without moving parts

- Media isolated sensing principle: no direct sensor contact with the fluid

- Compact and light-weight form factor

- Chemically resistant wetted materials

Applications:

- Failure detection and volume confirmation for diagnostics, cell analysis, and analytical instruments

- Process control and monitoring for coating, additive, and reagent dispensing systems