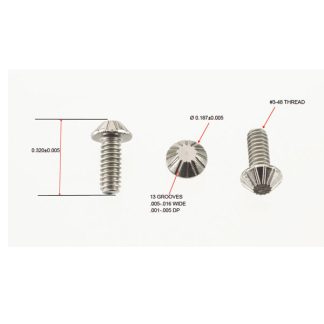

Description

This CRES fastener for a new product design in an airframe latch involved three different geometric challenges: a convex head feature, a reverse hex extrusion, and a rolled thread over a backward extrusion.

Sussex Wire created the convex head and hex-shaped reverse extrusion by cold forming the part in the first part of the process. As a result of the cold forming process, the hex created by the reverse extrusion created a stronger part than would have been possible by other means, such as machining, which would have significantly weakened the part. Sussex set up a secondary process to thread-roll the part without collapsing the hex cavity.

Use: Fasteners for Aerospace Industry

Material: Incoloy A-286

Manufacturing Method:

- Cold Heading

- Extrusion

- Reverse Extrusion

- Annealing

- Roll Forming

Critical Tolerances:

- Inset Hex Depth and Concentricity

- Head Height and Radius

- 8-32 Thread to AS8879, UNJC-3A

Advantages:

- 100% Net Shape – No material scrap

- Work hardened head-to-shank interface

- Work hardened threads per AS8879

- Final tensile at 130,000KSI, from original material tensile of 85,000 KSI

- Burr and silver free condition without mechanical secondary operation

- High throughput, low cost alternative to machining