Description

Description

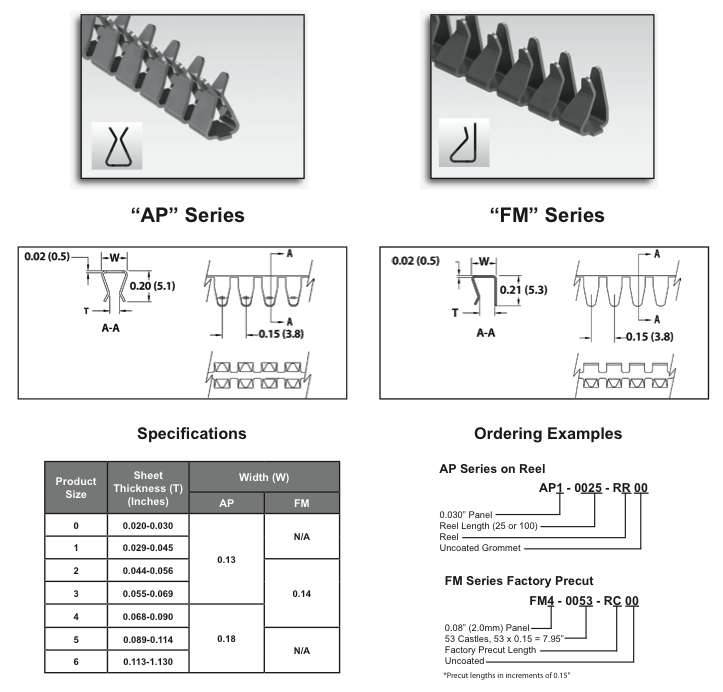

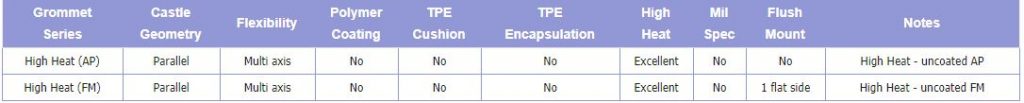

The High Heat Series consists of two un-encapsulated raw stainless steel metal only products.

They provide long term reliability for hostile high temperature environments.

They are low profile, multi axis conformable providing excellent grip strength and allow a low profile edge protection treatment.

The High Heat series are the AP and FM Series with no encapsulation. The FM variant provides a zero clearance flush mount capability.

Key Benefits

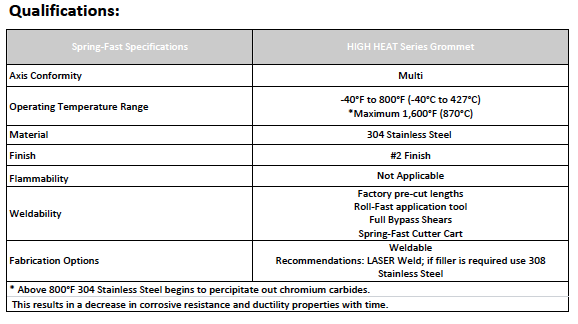

- Superior performance: 304 stainless steel goes where plastic and other polymeric grommets cannot be used.

- Fast and easy snap on installation, maintaining low installed cost benefits.

- At least 49% install cost savings vs. Teflon Grommets and glue.

- Improves efficiency 9.5x – due to fewer steps in workflow.

- Superior inherent grip strength from the stainless steel design.

Grommet Differentiation Table (GDT)

Applications

- Used in high heat situations: engine compartments, heat shields, exhaust systems, boilers, ovens, down hole drilling, furnaces, fastener to retain metal fabrics

- Straight edges

- Multi axis flexibility for flanged holes and small radii inside or outside corners

Features

- 304 stainless steel tooled to minimize burrs in extreme conditions

- Snaps on fast with finger pressure

- Installs continuously with multi axis conformity

- Self locking with strong retention

- Easy maintenance due to its ease of application and removal

Key Specifications

- Resistant to hydrocarbons, immersion, salt spray, shock and vibration

- Operating Temperature Heat continuous to -40°F to 800°F (-40°C to 427°C)

- High Shock and Vibration Resistance to rms G 41.7

- AP-High heat: Fits edge thicknesses: 0.020” to 0.130” (0.5 mm to 3.3 mm)

- FM-High heat: Fits edge thicknesses: 0.044” to 0.090” (1.1 mm to 2.3 mm)

- Factory discrete cut lengths and reels: 25 ft. (7.6 m), 100 ft. (30.5 m), 500 ft. (152 m)

- Tools available: Installation roller, full by-pass shears, castle removal, measuring scale,

go-no go sizing gauge, cutter cart