Description

Standex Electronics is a leading manufacturer of electronic components that include power magnetics, sensors and switches. As a division of Standex International, we draw from experienced design and manufacturing professionals around the world to create high-quality planar magnetics and provide bespoke design services to global customers.

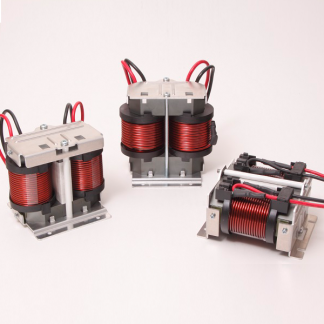

Operating from our Cincinnati, OH, headquarters, one of Standex Electronics’ specialty products include planar transformers and inductors. These components are unique in that they utilize flat copper conductors instead of traditional magnetic windings. Unlike traditional magnetics, which wrap wire around a central core, planar designs are more efficient because they can incorporate compact stacks and precise fabrications.

Benefits and Features of Planar Magnetics

Planar magnetics are built to perform in demanding applications that require robust power and reliable performance. They were originally designed for military and aerospace applications. Now planar magnetics have started to spread to other industries that can make use of their smaller weight and component footprint as well as their highly repeatable electrical characteristics.

- Highly robust design: Traditional wirewound magnetics always have a degree of variability as they include manual windings. Planar magnetics, on the other hand, eliminates this source of variation by eliminating the manual windings. Instead, planar magnetics are constructed by stacking windings together, which greatly reduces part-to-part variability and. This makes them ideal for mission critical applications that demand strict quality assurance standards.

- Best in class power density: Planar magnetics have a compact and efficient design. Due to their stacked construction, planar magnetics are able to better utilize a given footprint. Effectively, the planar design allows more of the copper to be used compared to a traditional wire wound design. As a result, planar designs can achieve at least 99% efficiency and produce higher ranges of power compared with traditional windings of similar material weight and volume.

- Easy cooling and temperature control: Electronics need to have a reliable way to control temperature so they can guarantee optimal performance. Planar magnetics have tightly stacked components that allow for simple cooling mechanisms, optimized for heat dissipation through conduction. Dedicated heat sinks and cold plates can adequately cool the parts to keep them performing at a superior level. Alternative designs and traditional windings require more energy or alternative methods to provide equivalent cooling.