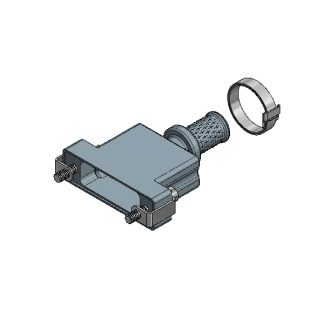

Description

Locking fasteners are threaded fasteners that are either male (like a stud) or female (like a nut), which are pressed into a hole previously drilled into a chassis or housing. They can be installed with ordinary tools and offer high durability. Their integral, captivated design speeds handling and assembly operations in a wide variety of applications in the electronic, instrument, aircraft and other industries. The ability of these fasteners to provide long-wearing stainless steel threads for aluminum, brass, mild steel, thermoplastic panels or chassis makes them ideal for fastening components, terminal boards, wire and cable harnesses, circuit boards, tube sockets and sub- assemblies. Their extreme durability makes them a must where repeated fastening and unfastening takes place. The unified design of the Floating Nuts simplifies adjusting hole misalignments, particularly in difficult-to-reach places. Self-locking styles provide added resistance to vibration and shock in fastening applications.

Locking fasteners are most commonly made of stainless steel or steel, but in some cases aluminum can be used as well. Sizes range from 0-80 up 1/2-13 Thread or M2 to M12.

ASM’s refined manufacturing processes can hold tighter tolerances than the industry standard and allow for the fastest turnaround of parts as needed. Part lengths can be modified to suit any customer requirement. ASM’s quality management system is AS9100D and ISO9001:2015 certified. DFARS documentation is available upon request.