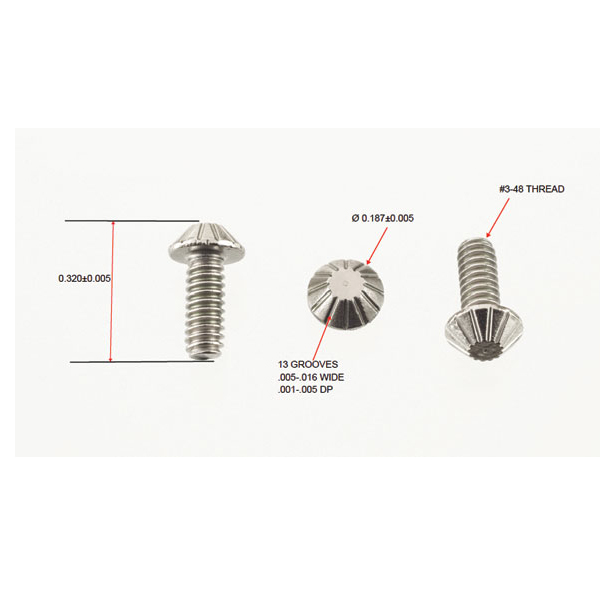

Description

Sussex Wire designed a net shape micro screw producing no scrap, and in the process, developed machine automation and sensor controls to ensure six sigma yield while eliminating costly inspection by the customer. Sussex Wire’s proprietary manufacturing cell control system eliminated the pre-existing condition of malformed and contaminated parts reaching the company’s customer.

Manufacturing Method:

- Cold Heading

- Upsetting

- Micro Threading

- Proprietary Thread and Concentricity Detection System

Sussex Wire is a global pioneer in collaborative design, development, manufacture and control of miniature and micro-miniature metal components for customers seeking a better solution for yield, strength, assembly and cost through the application of cold forming technologies.

Mechanical design and assembly firms the world over turn to Sussex Wire for their most advanced near-net-shape part requirements to eliminate material scrap, increase mechanical strength and reduce costly secondary operations.

Sussex Wire employs vertically integrated LEAN practices in design, manufacturing, order and global inventory management including stock custom miniature and micro components for JIT delivery to international customers in the Medical, Automotive, Aerospace, Energy, Appliance, Consumer Electronics, Defense and Semiconductor markets.

Our engineering team applies advanced progression, materials characterization, tooling and manufacturing knowledge to develop cost-effective production routines for each customer’s requirements.

Using finite element analysis, quick-turn prototyping, CAD/CAM, soft tooling and in-house tool-making, Sussex has the depth and capabilities to move your project quickly into production.

Advantages:

- 100% Net Shape – No Material Scrap

- Six Sigma in process controls

- Work hardening enhances component durability and product life cycle

- Custom contamination-free manufacturing cell