Description

Description

The SL Series has a steel substrate fully encapsulated in flexible, lubricious TPE

for superior abrasion and chemical resistance.

It has 4-axis flexibility and acts as a best in class grommet edge or a high performance edge trim.

Key Benefits

- Superior performance: encapsulated stainless steel core: outperforms plastic grommets.

- Snap on installation lowers costs 49% vs. grommets with glue. Watch the 4 min. video below.

- Improves efficiency 9.5x – due to fewer steps in workflow.

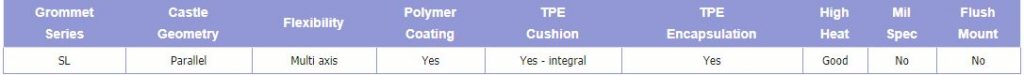

Grommet Differentiation Table (GDT)

Applications

- Used in high performance applications: aircraft structures/interiors, avionics systems,

military vehicles, NASCAR vehicles, supercomputers, medical equipment and rail transit - Straight, roll formed and flanged edges

- Multi axis flexibility for flanged holes and small radii inside or outside corners

- High performance edge trim

Features

The old nylon grommet with glue is old, inefficient and costly. DTi has a better way.

- 100% TPE encapsulated stainless steel substrate

- Snaps on fast with finger pressure

- Installs continuously with multi axis conformity

- Self locking with strong retention with no adhesives

- Simpler install: no adhesive, fixturing, curing, clean up or OSHA concerns

- Maintenance is far easier due to its ease of application, use and removal

- Customization available (lengths, colors and print)

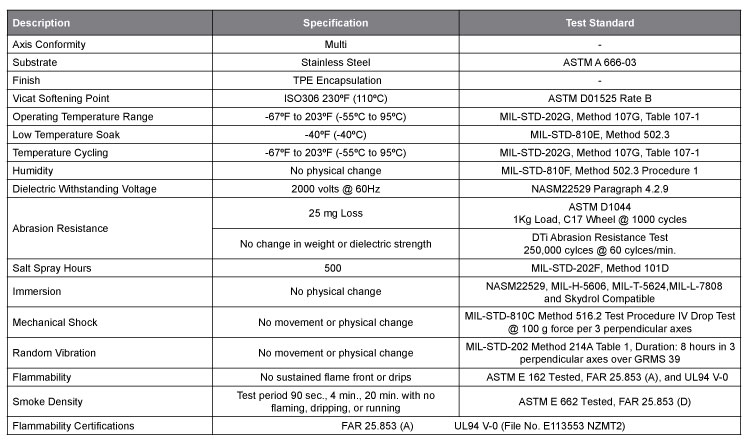

Key Specifications

- Resistant to hydrocarbons, immersion, salt spray, shock and vibration

- Operating Temperature Heat continuous to -67°F to 203°F (-55°C to 95°C)

- UL94 V-0 Flammability Rating

- RoHS and DFARS Compliant

- High gripping strength, corrosion resistance and dielectric strength

- High Shock and Vibration Resistance to rms G 41.7

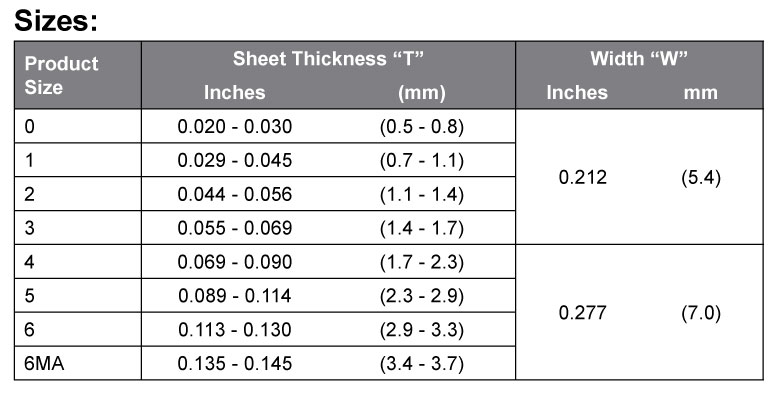

- 7 sizes to fit edge thicknesses: 0.02” to 0.145” (0.5 mm to 3.7 mm)

- Factory discrete cut lengths and reels: 25 ft. (7.8 m), 100 ft. (30.5 m), 500 ft. (150 m)

- Tools available: Installation roller, full by-pass shears, castle removal, measuring scale,

go-no go sizing gauge, cutter cart

![LP[G]MM 'Great White' | MiMo 2G/3G/4G, Optional MiMo WiFi + Optional GPS Vehicle Antenna](https://amaze-electronics.com/wp-content/uploads/2025/12/LPGMM-Great-White-324x324.jpg)