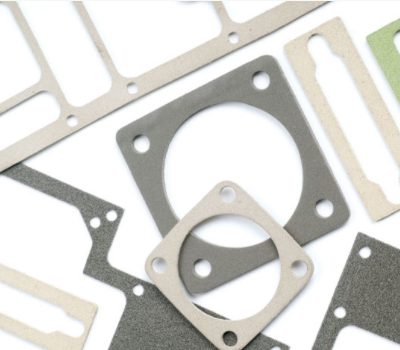

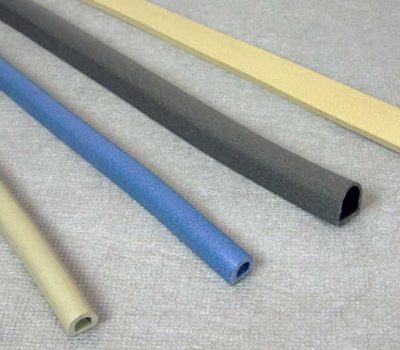

Flat gaskets are cut from moulded sheet using state of the art reciprocation knife cutting technology or rule dies. Larger gaskets can be cut from moulded or fabricated picture frames. This option has the advantage of saving material and allows larger gaskets to be produced most efficiently. Fabricated frames use either extruded or moulded flat section that is joined by vulcanizing the polymer. We use the same conductive polymer compound to vulcanize the joints ensuring complete electrical conductivity is maintained across the joint. This process has allowed Kemtron to produce gaskets up to 2 metres long, with the same mechanical and electrical integrity as found in a single part gasket cut from sheet. This method of manufacture often offers cost savings over cutting from sheet which creates significant loss of waste material. Our in-house production facilities are suitable for prototype, short and medium production runs, as well as commercial quantities.

Performance

Kemtron’s Electrically Conductive Silicone Elastomer materials tests are performed in house and by external laboratories all using calibrated equipment, testing to the standard specified in MIL-DTL-83528. Kemtron offer the performance data and methods of testing to MIL-DTL-83528 for comparison only.

All of Kemtron’s test certificates and reports are available upon request. The results were obtained in laboratory conditions and should be used as a guide only. Customer hardware and many other factors are beyond our control. Therefore, customers should perform their own tests to ensure suitability of the product for the desired performance.

Materials

- Silver-plated aluminium in silicone or fluorosilicone

- Silver plated copper in silicone or fluorosilicone

- Silver plated glass in silicone or fluorosilicone

- Nickel coated graphite in silicone or fluorosilicone

- Pure nickel in silicone or fluorosilicone

- UL94V0 grade of nickel coated graphite in silicone

Applications

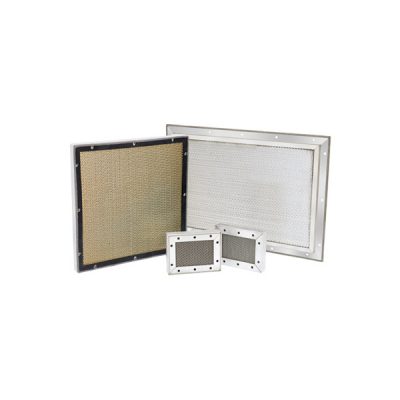

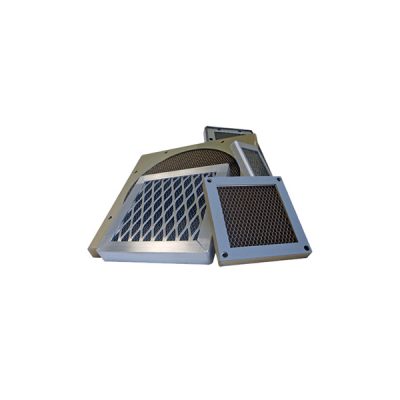

Surface mounted gaskets are to be used where groove mounted gaskets such as O-Rings cannot be accommodated.

With surface mounted elastomeric gaskets, the aim should be to limit the compression of the gasket to between 10% and 20%. 10% is the minimum recommended compression with a solid silicone style of gasket. (Some form of compression stop or limit is essential with surface mounted gaskets to prevent over compression). Compression stops can be built into many styles of gasket or made as an integral part of the flange. Their height should equal that of the maximum compressed height of the gasket. Compression stops fitted into gaskets can be in the form of collars or washers so that fixing bolts can pass through them or as solid studs located either side of a fixing bolt. We can supply a range of standard stops and collars in stocked materials. We are also able to offer special sizes and materials as required.

- Industrial controls

- Instruments

- Military equipment

- Avionics

- Medical electronics

- Electronic equipment enclosures’