Types of Constant Force Springs & Variable Force Springs

Constant Force Springs

Constant Force Springs provide a smooth and efficient force for moving product in a POP (point-of-purchase) slide tray, regardless of whether the tray is made of plastic, wire or corrugated material. The springs take up very little space, are economical, and easy to assemble.

Sample Kits

Samples of our constant force and variable force spring product line are available in various Sample Kits, free of charge, to assist you in designing your next project. Send us samples of your trays and product, and then we can assist you in selecting the right spring for your application or design. Contact us using the information towards the bottom of this page.

Variable Force Springs

Variable Force Springs are recommended for applications where a stronger force is initially required to move the product. As the product is removed, the variable force spring automatically adjusts to the lighter load, which provides smooth product transition. Like the Constant Force Springs, they are also economical, easy to assemble, and use little space.

Reel Retrievers & Mini Reels

Reel Retrievers & Mini Reels

The Reel Retriever is a device which offers theft deterrence and customer convenience for POP displays. A compact box which is securely fastened to a display contains a spring-loaded, retracting cable assembly. The reusable cable is positively attached to the product, allowing customers to handle products in stores while the products remain secure and displays are kept in order.

The Mini Reel is our small profile solution for projects requiring maximum security with minimum space. The compact design has a slim profile that provides the same security as our full size Reel Retriever

Cable lengths are available at 6″ up to 72″.

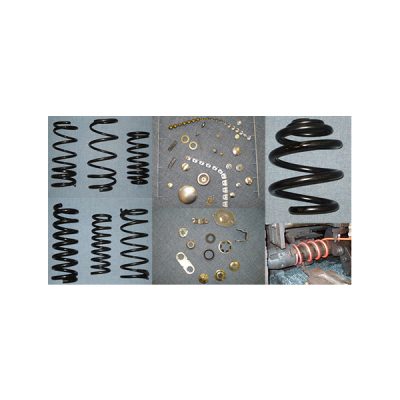

Standard spring ends include: small eyelet, large eyelet, round dome, loop, ball, crimp, spring, reusable and self-centering magnetic end. Custom spring ends are also available.

Slideline™ Pusher Systems

Slideline™ Pusher Systems

Slideline™ Pusher Systems maintain appealing merchandise displays by utilizing spring tension that automatically repositions the product. This results in organized, efficient, and attractive display. When a product is removed from these neatly aligned display trays, spring tension automatically repositions the row of products and the next item is automatically pushed to the front. Slideline Pusher Systems can be customized to fit any shelf size and fixture configuration.