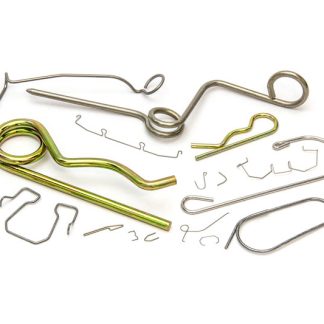

Description

An extension spring is a part that captures energy and develops force used to execute an action. The “initial tension” is created during manufacturing when the wire is rotated backwards during coiling. When you pull the spring apart, you are undoing the rotation, which develops force or initial tension.

Extension springs are used in a wide variety of applications where a precise amount of force is required at a certain deflection. They can range dramatically in size (1/2-inch to 50 feet) and in the force they create (ounces to thousands of pounds). To illustrate the point, they can be pulled an inch or 100 inches.

Extension springs are used to retract aircraft landing gears and to tether equipment to oil rigs in off-shore applications. They are used on Class 8 heavy trucks as hood-assist springs to safely hold the hood in place for engine maintenance. Other examples include specialized springs implanted in roads as anti-terrorism barriers to provide security for military buildings and other potential targets.